Small scale BusseGT systems for complete installation in houses for 250 / 500 / 750 Gal/d

Small scale BusseGT systems in combination with existing septic tanks for 250 / 500 / 750 Gal/d

Small scale sewage treatment systems BusseGT for 1000 Gal/d

Small scale sewage treatment systems BusseGT for 1500 Gal/d

Small scale sewage treatment systems BusseGT for 2000 Gal/d

How it works

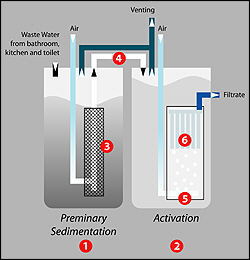

Diagram of the functional principle of microfiltration technology

The Busse MF Small Size Sewage Treatment System is designed on the basis of DIN 4261 part 2 and is comprised of two treatment steps, pre-treatment (1) and aeration (2). At the pretreatment step, which also serves as waste water storeage, biologically degradable coarse material such as, e.g., faeces, toilet paper, are dissolved and the non-dissolving components separated from the waste water by an aerated sieve (3). A pump (4) pumps the water, from which the coarse material has been separated, to the aeration section. In this step the organic matter in the waste water is degraded biologically by microorganisms and oxygen (5). In addition to this, the waste water is treated physically by microfiltration membranes (6) (ultrafine filter with 0.4 µm pore size). These membrane filters eliminate suspended material, as well as bacteria and germs, ensuring that only totally clear, odourless, hygienically harmless water (filtrate) leaves the system.

The BusseGT has passed the certification process of NSF International Standard 40 and 245 for USA and North America in 2008. The test results show that the system elates over 95 % of the COD and over 95 % of BOD5. It has been proven during the certification process that the BusseGT system using microfiltration membranes can hold back all bacteria and viruses and therefore also meets the requirements of the Washington State Legislature Hygienic Standard. The filtrate is fit for re-use without further treatment.

Design Approvals

BusseMF plant on the test field of the PIA Aachen 2008

The BusseMF domestic waste water treatment system received the of Deutsche Institute für Bautechnik DIBt certification Berlin in 2001 it was the first small scale system with MBR technology that was certified in Germany.

Ten years after the development and market launch of the BusseMF the system was again certified by the testing institute PIA of RWTH Aachen. The new European water framework directive required certification of the system according to EN norm 18333 necessary, because of the higher requirements for relevant reduction standards (reduction of carbonate, nitrate and phosphorous). The BusseMF surpassed all test parameters and can therefore be used even in very sensitive water protection areas, such as drinking water protection zones and nature reserves.

The German Institute for Civil Engineering confirmed three new design approvals issued in 2010 that the BusseMF meets all the requirements for all known reduction standards. The design approval number Z-55.3-60 confirmed the reduction standards for N + H, the design approval number Z-55.3-317 confirmed the reduction standards D + H and number Z-55.3-327 the reduction standards D + N+ P. The local water authorities define which reduction standards have to be met in which region. According to that definition the BusseMF is equipped to meet the required standards for the respective regions.

NSF International

On the test field of the NSF in the U.S.A. (2008)